This video is NOT exactly the machine that is being listed for sale but only a close representation see details below

MACHINE FEATURES:

- Fixed Bridge (moving table) type machine equipped with 2 (two) 18 HP 4-pole air-cooled router spindles,with grease lubricated ceramic bearings, dual 10-Position Automatic Tool Changing Systems, with one tool length touch probe.

- The spindle motor is powered by an electronic AC inverter drive system with dynamic spindle braking.

- Full Torque is achieved at 9,000 RPM & Full HP is achieved at 12,000 RPM.

- Tool Changer Carousels are mounted on the spindle carriage, next to the Router Spindle, for fast & efficient tool changes.

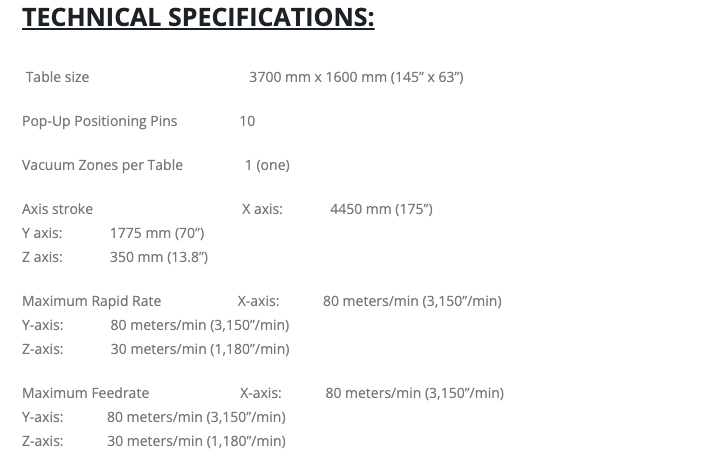

X & Y axes are constructed of massive, heavy-duty welded steel construction with multiple reinforcements to increase strength and absorb vibration. Z-axis spindle carriage is a specially designed Meehanite casting for high strength and inherent vibration dampening characteristics with a pneumatic counterbalance system for smooth & accurate operation.

Spindle #1 & #2 – Router Spindle – (350-900mm adjustable)

Spindle type Anderson 4-Pole

Motor power 13.5Kw (S6): 11Kw (S1)

Spindle speed (RPM) 1000-22000

No. of changeable tools 10 per tool changer

Spindle nose HSK63F taper

FANUC OiMD Controller System + Windows PC Front End User Interface

This Anderson CNC Proudly uses the latest, Series 0i-MODEL D, with nano-resolution performance. With over 700,000 systems installed, the 0/0i from FANUC is by far the world’s most popular CNC control. The Series 0i-MODEL D achieves the highest precision possible, with nanometer resolution standard throughout the CNC system.

Fast, high resolution 16-million count-per-revolution feedback devices combine to provide a superior surface finish quality when contouring. This minimizes the need for secondary operations, reducing delivery times & part cost.

HANDHELD REMOTE PENDANT:

This Standard Feature simplifies feed rate & spindle speed overrides from anywhere around the machine, as well as an additional E-Stop function. The HPG jog wheel also allows for manual jogging of the machine, stepping manually through a program, or manual movement or verification of a single axis. This pendant comes corded for portability & convenience.

Vacuum hold down system: